BLOG

Exploring challenges and opportunities for a circular economy in Sesvete

Exploring challenges and opportunities for a circular economy in Sesvete

Exploring challenges and opportunities for a circular economy in Sesvete

From meat factory to urban mine

Words by CENTRINNO Pilot Zagreb & Metabolic

ABOUT THE PILOT AREA

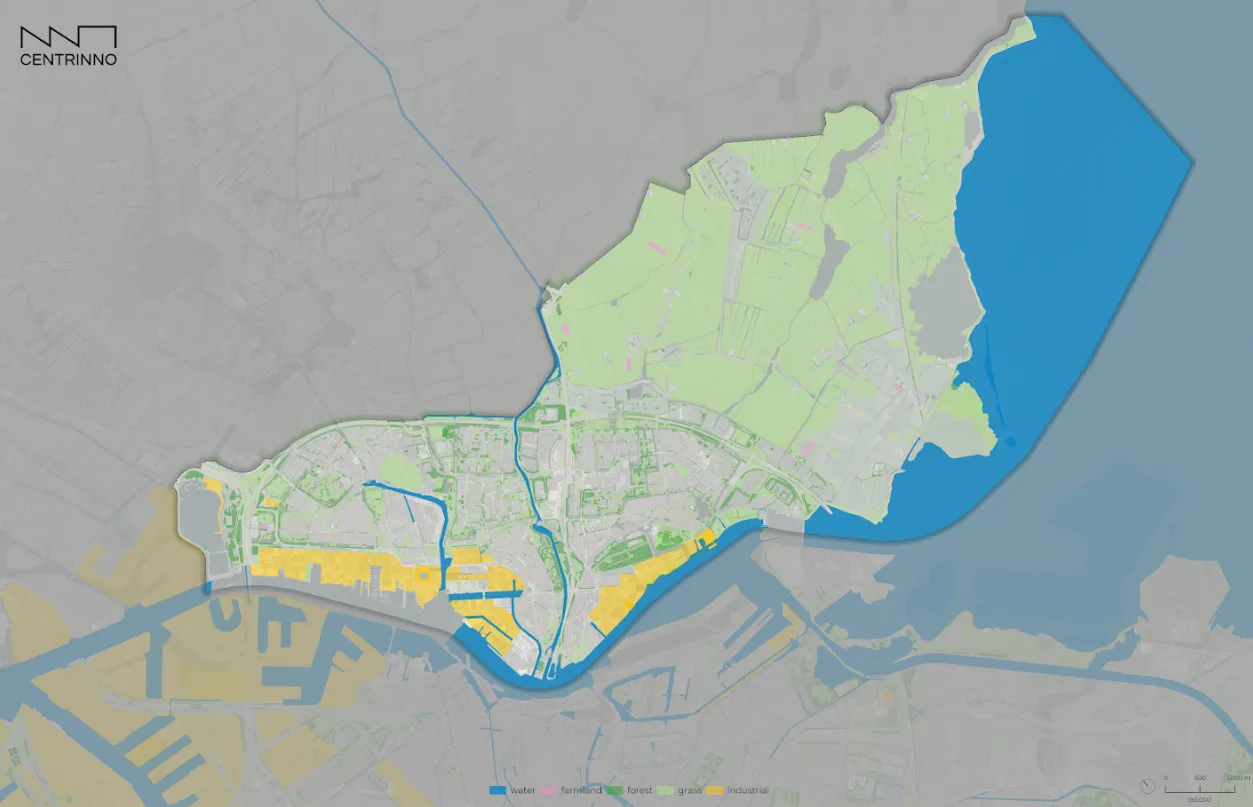

Pilot area: Sesvete (Zagreb)

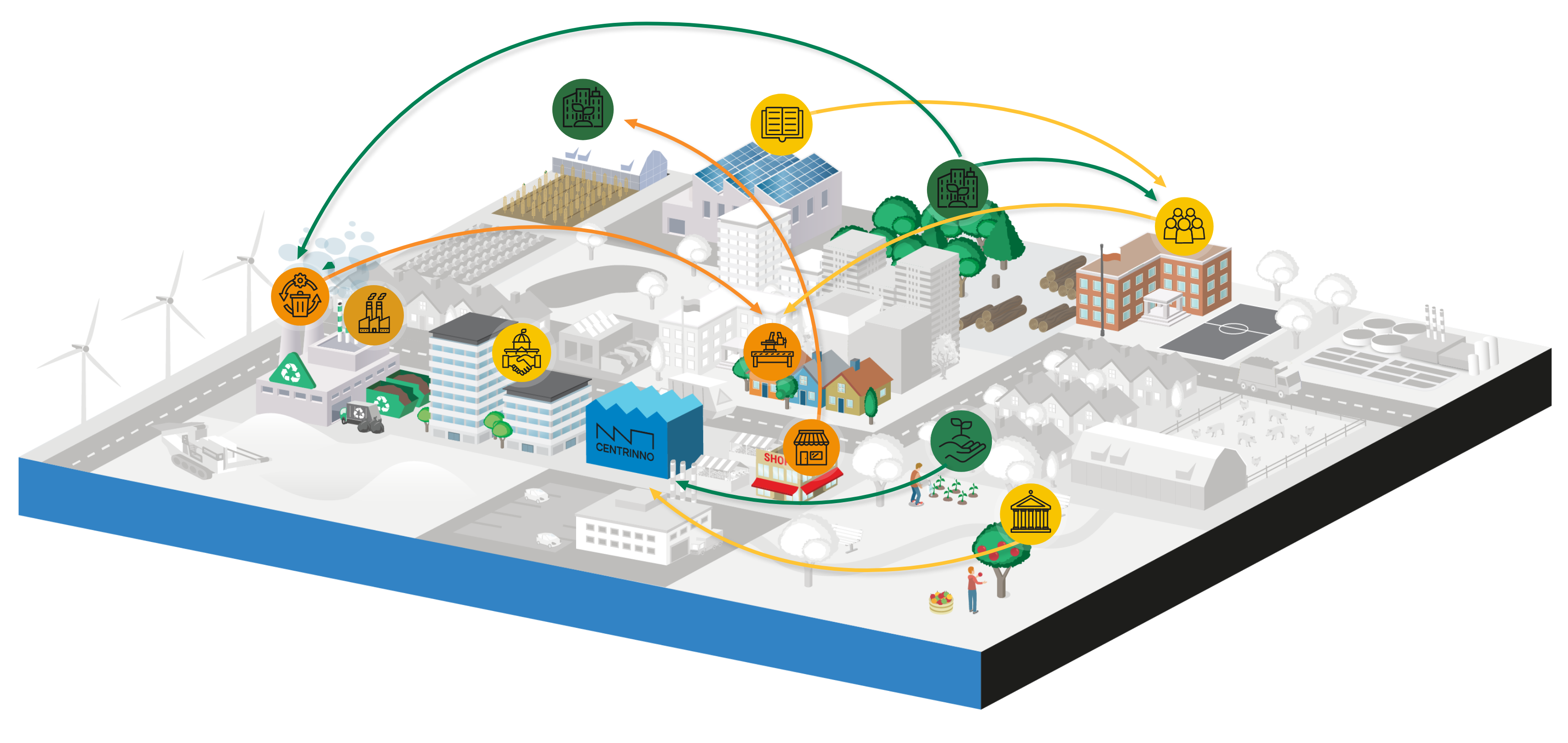

How can a former meat factory become a case study to teach and inspire the local community about the potentials of a circular economy? The pilot team, consisting of members of the Faculty of Architecture and Fab Lab Zagreb, have mapped the reusable resources within one of Zagreb’s abundant brownfields awaiting their demolition. Following Zagreb’s mapping story, we can learn how we can map resources at a micro-scale of one building.

Mapping the reuse potential of building materials in Zagreb’s brownfields

The Croatian capital of Zagreb is a diverse city, well known for its architectural style and prowess. However, it is also a city facing challenges similar to others around Europe, struggling to move towards greater circular material reuse and recycling rates. While the municipality is starting to take first steps to become a city without landfills, there is still a long way to go.

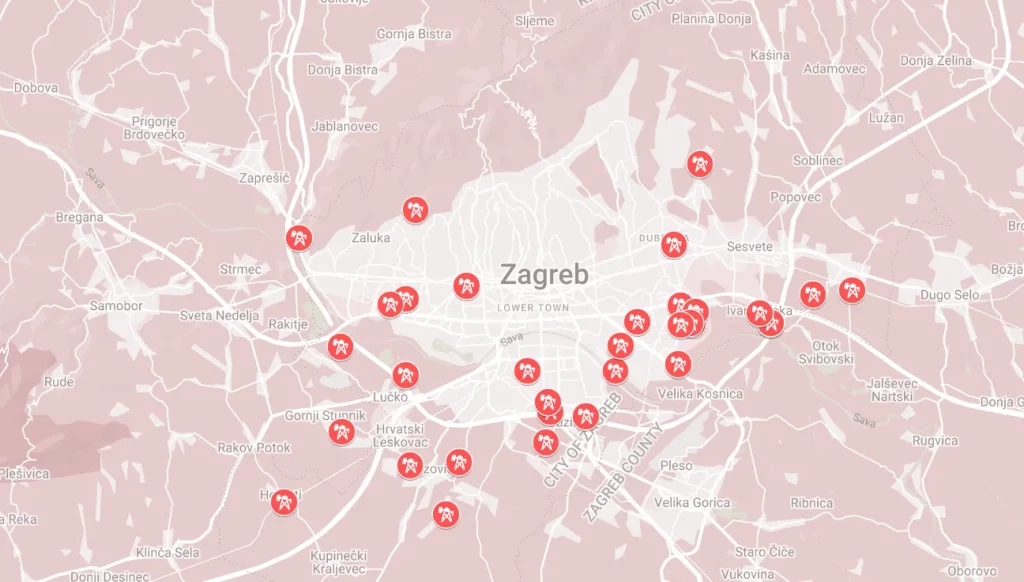

Besides household waste sorting, construction waste and its sustainable management is a significant problem for Zagreb. Just like in many other cities around the world, urban development, renovation needs of older buildings, and maintenance and construction of novel infrastructure, houses and offices are important topics for the city of Zagreb – especially after the 2021 earthquakes. These developments call for a large amount of investments. Making sense of the scale of this problem is not easy since data on how much construction waste the city generates – and where it goes – remains lacking. To get a preliminary insight into the city’s construction and demolition waste problem, and hence its underused reuse potential, the CENTRINNO pilot in Zagreb set out to map all known illegal construction landfill sites within the city boundaries.

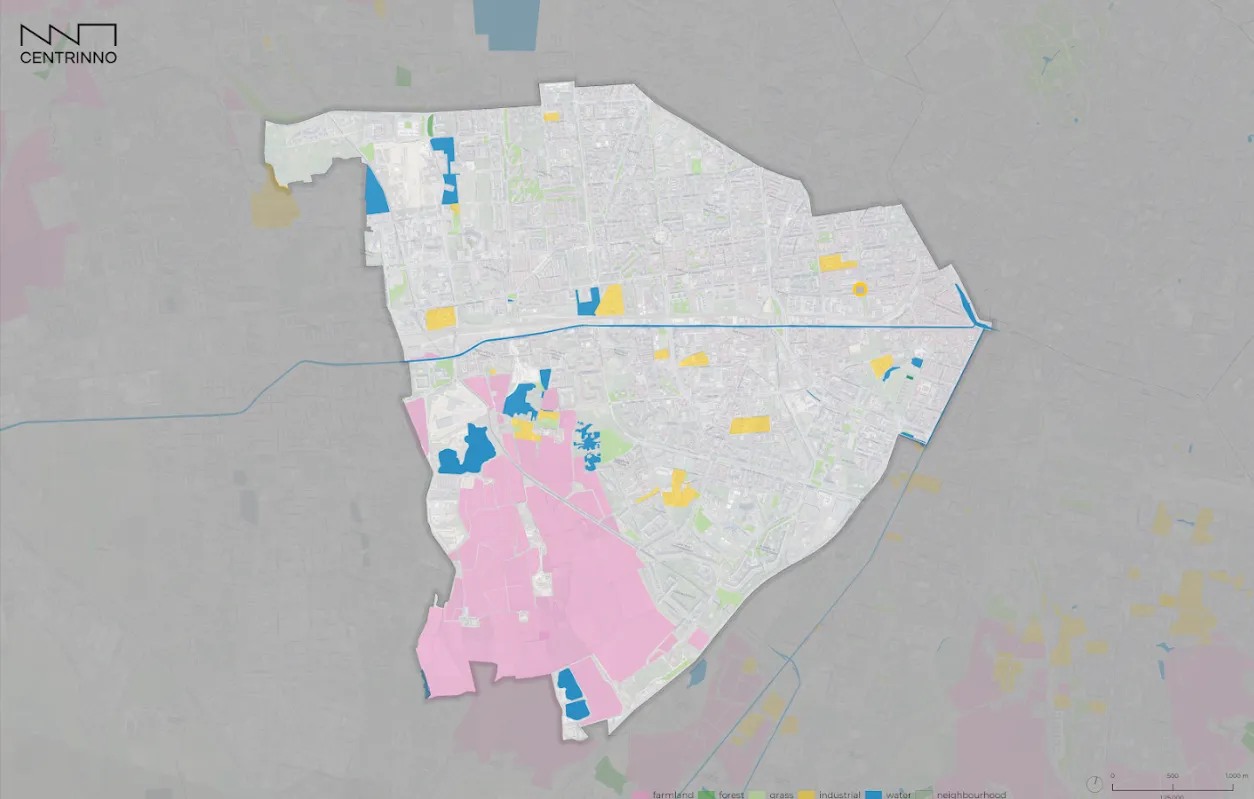

Map 1: The locations of unofficial (illegal) construction waste sites in Zagreb. Source: [1]

With over 30 sites, it is clear that local construction waste management practices can immensely profit from improved education and inspiration surrounding the circular reuse and recycling potential of wood, steel, concrete and bricks.

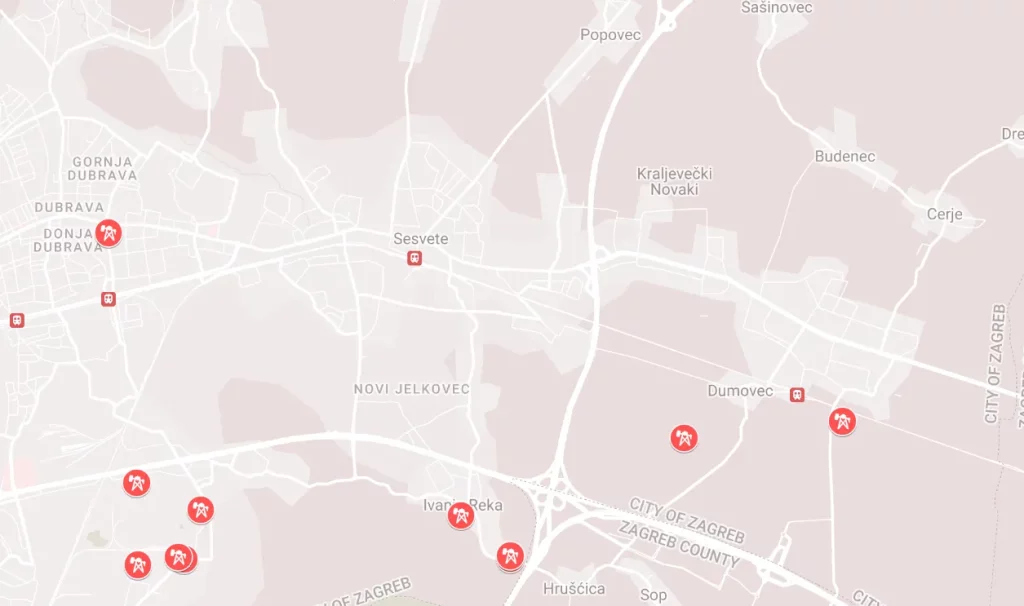

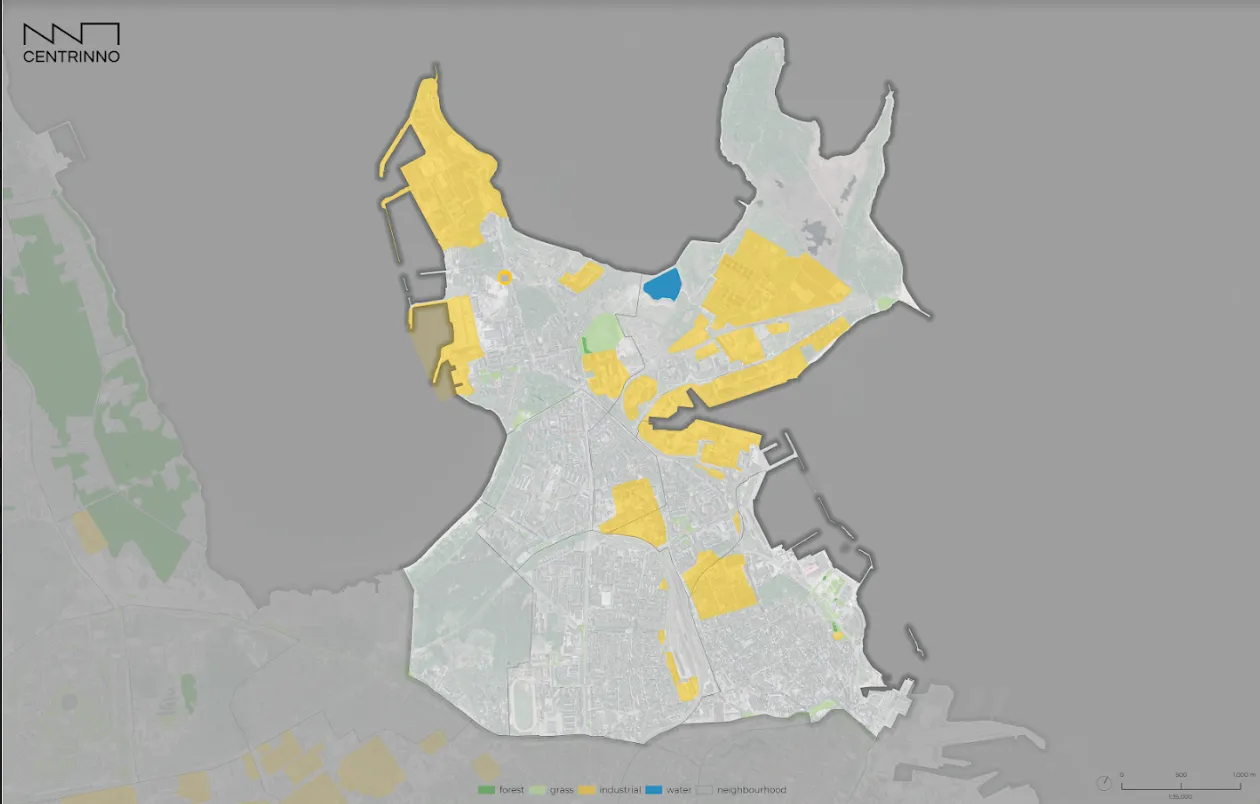

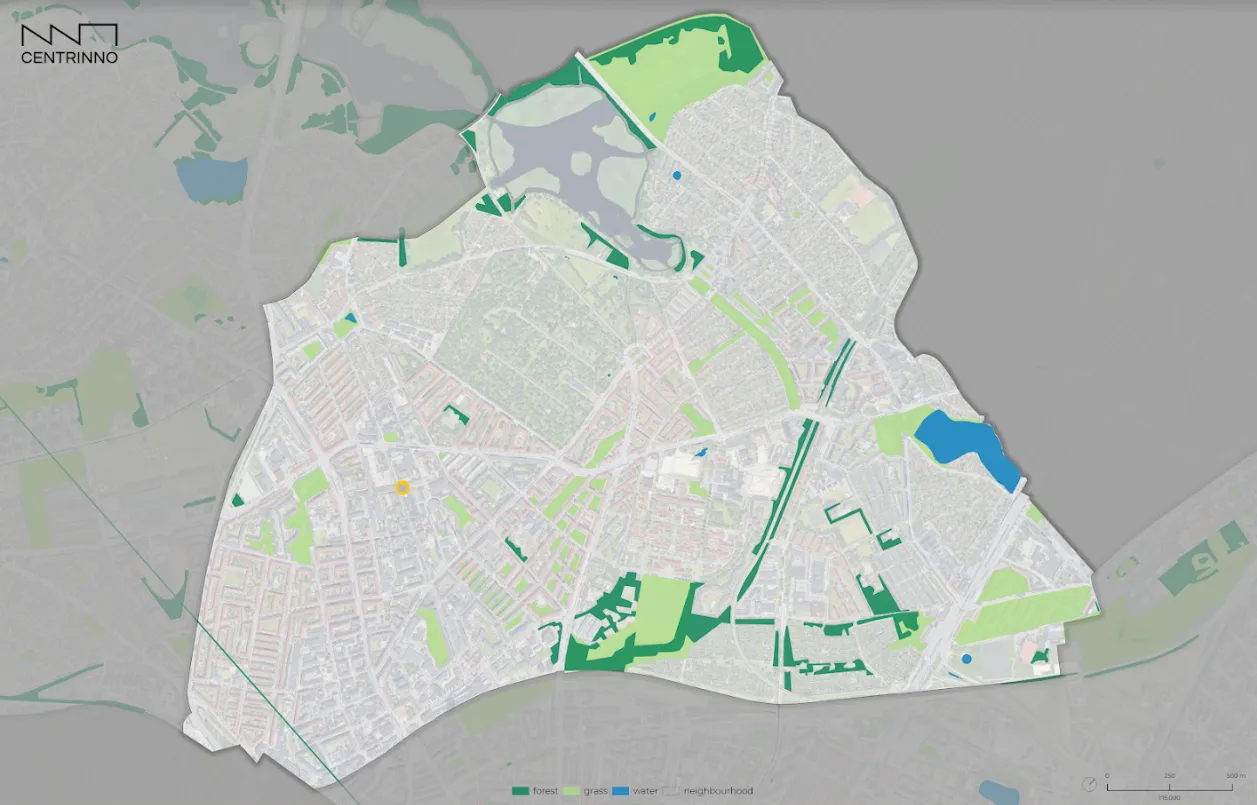

It is not only the new construction and renovation of houses and offices that provide an opportunity for material recovery! Zagreb has a vast repertoire of brownfields and to-be-demolished factory buildings that store significant volumes of resources for which we should find better utilization pathways in new construction or onsite renovation. An overview of all currently known brownfields gives us a first idea of the extent of this urban mine.

Map 2: the locations of brownfields throughout Zagreb. Source: [2]

Map 2: the locations of brownfields throughout Zagreb. Source: [2]

The CENTRINNO pilot in Zagreb aims to explore this untapped potential resource – the city’s urban mine – to educate, innovate and showcase circular solutions to renovation and demolition, using the former Sljeme meat factory – and future Fab Lab – in Sesvete as an example. The Sljeme factory is a great starting point for us to learn what types of materials can and cannot be reused before we can extrapolate these learnings and apply them to the landscape of brownfields across the city. So let us dive a little deeper into Sesvete and the Sjeme factory.

The pilot neighborhood: Sesvete

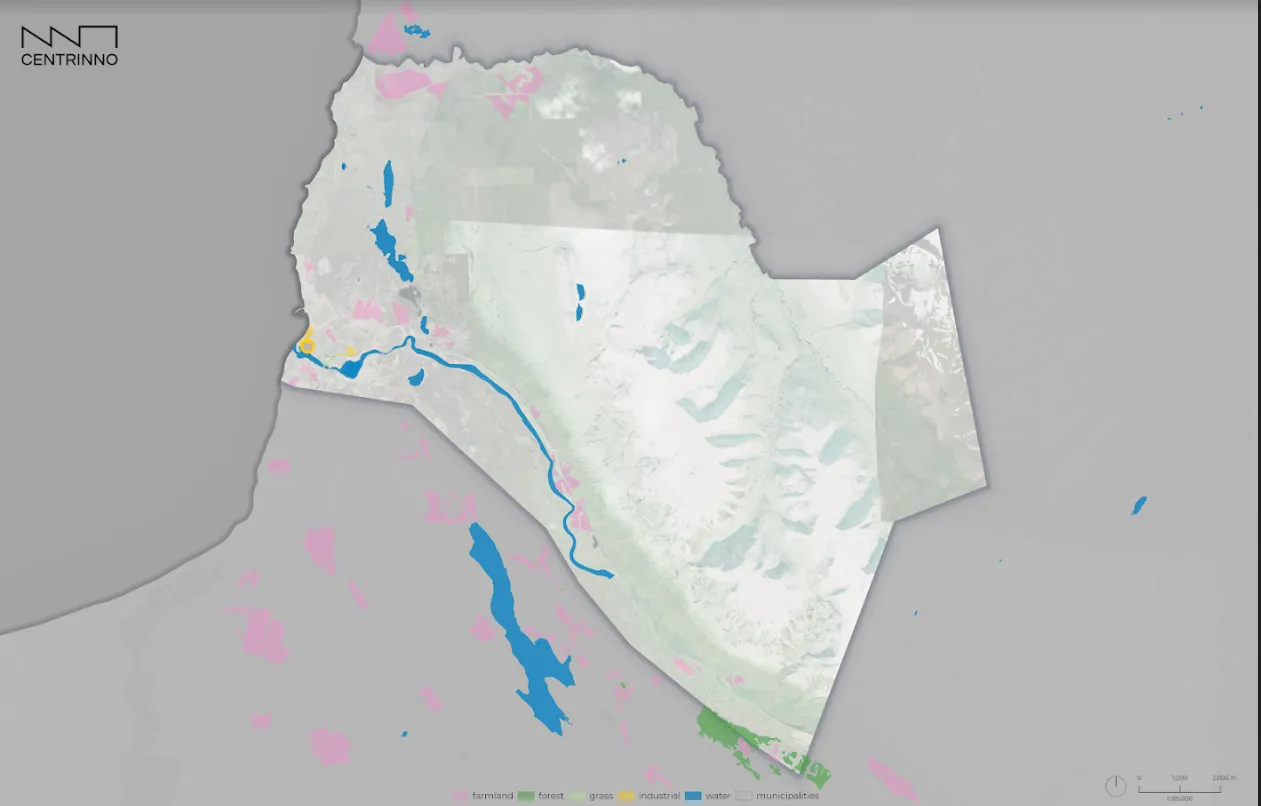

The Zagreb pilot is located in the Sesvete neighborhood, which in turn is situated in the similarly named district. While the district itself does not seem to be a hotspot for illegal construction waste dumping, the area has great potential for urban mining and thereby the recovery and reuse of construction materials.

Map 3: Illegal construction waste sites in the Sesvete area. Source: [1]

Like so many post-industrial buildings in Zagreb, the Sljeme factory, a former meat production plant within Sesvete, is set to be partially renovated and reused, but also partially demolished. This project offers a prime opportunity to serve as an exemplary case for the local repurposing and reuse of ‘waste’ materials – in that sense performing as an urban mine.

?

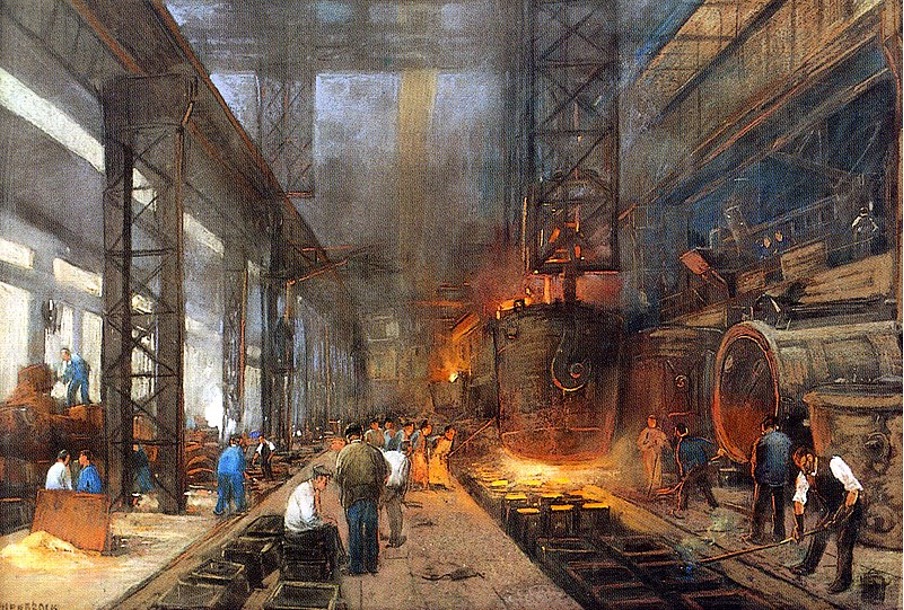

The Sljeme factory

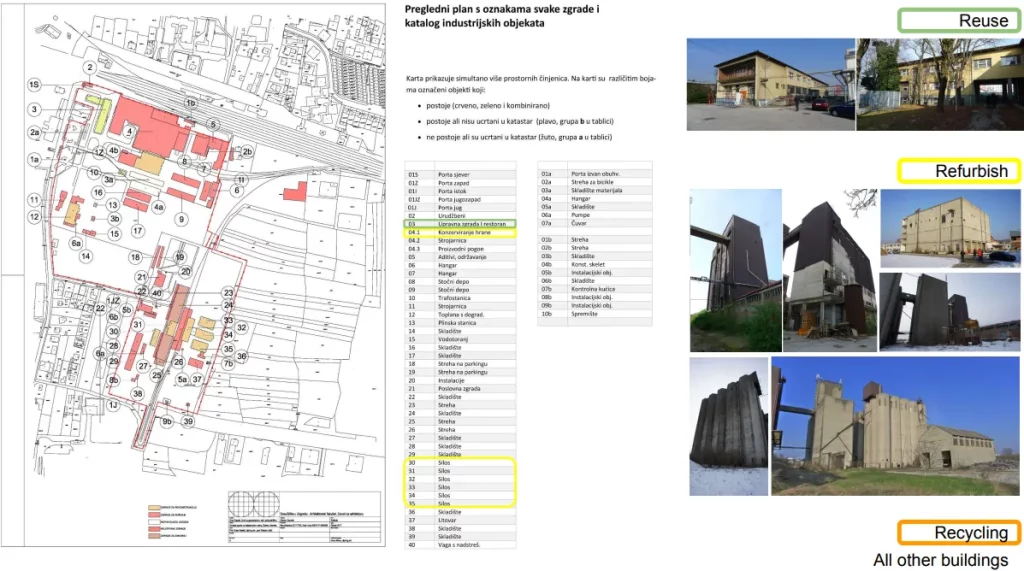

Established in the late years of the 19th century, the Sljeme meat production plant was created in the times of strong socialism. It was one of the main meat producers for then Yugoslavia, which it remained for a period of over 120 years. However, after marketization entered the status quo in the later 20th century, the production plant began to struggle, and went out of service in 2006. Now, in 2022, the plant is finally getting its long overdue reutilization. Aiming to reuse and recover as much of the plant’s buildings as possible, we mapped out which buildings are fit for reuse, which need refurbishment and which need to be demolished for material recycling.

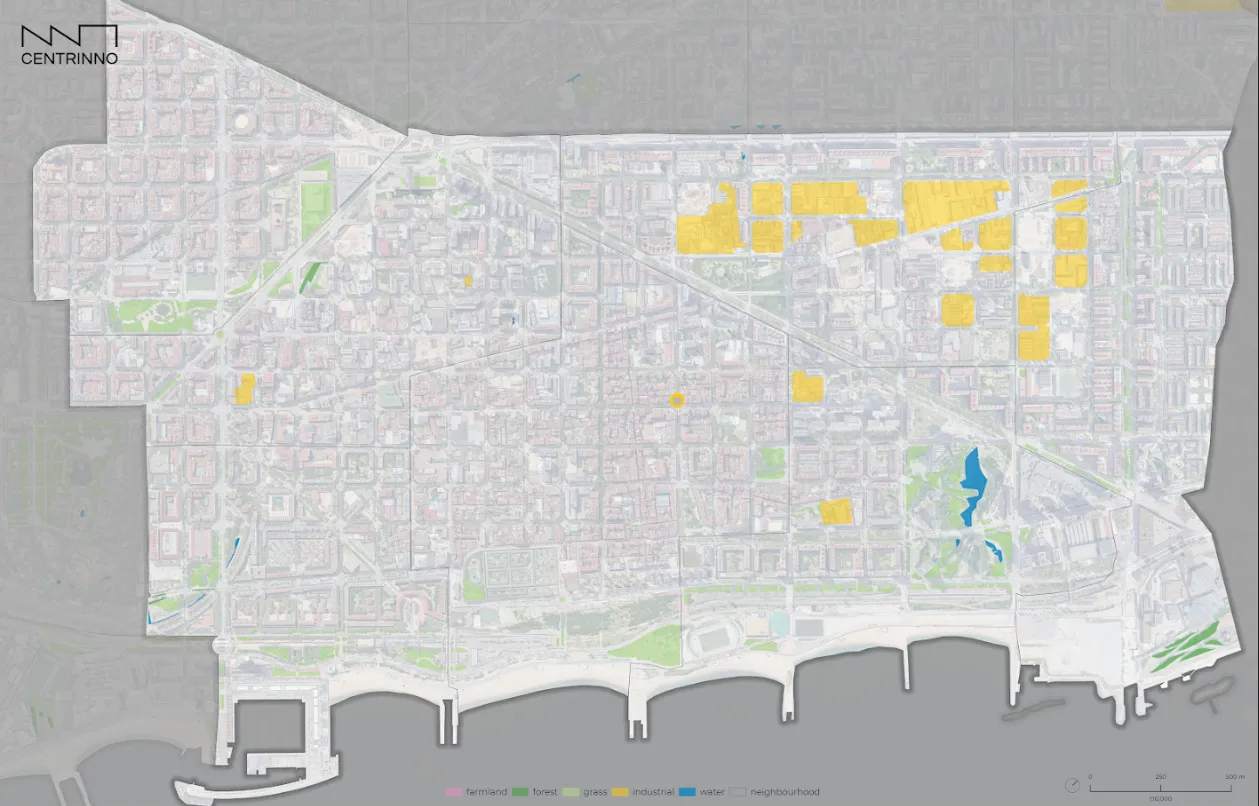

Map 4. A layout of the changes envisioned to the Sljeme meat factory plant

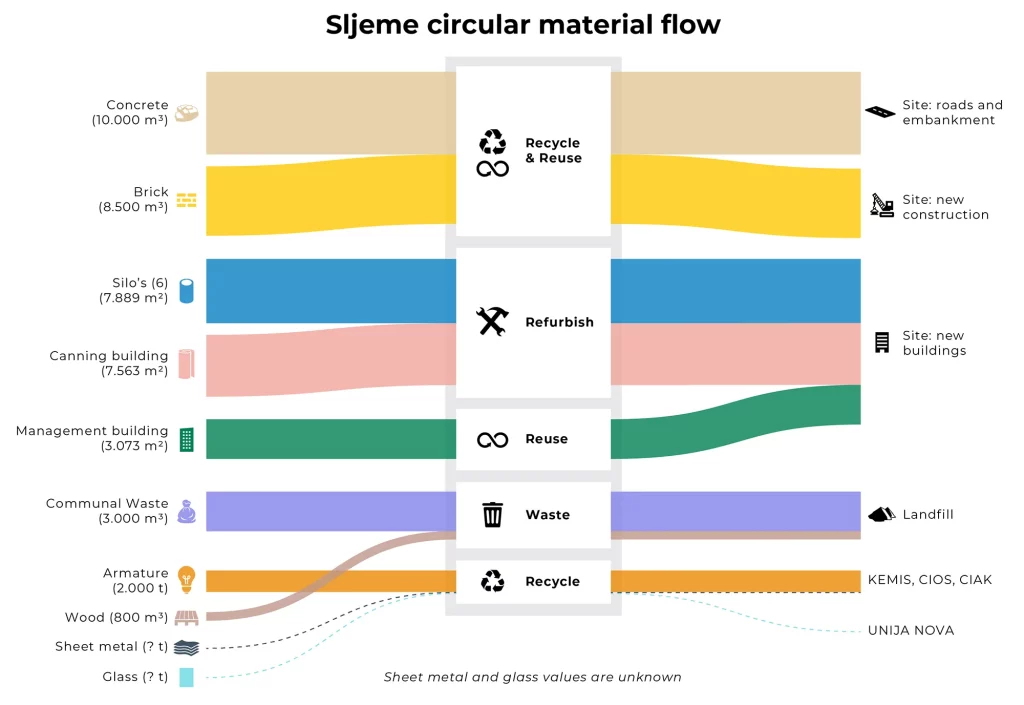

In a circular stream, we aim to retain as much of the buildings as possible since reuse and renovation of whole building structures is generally preferred over new construction or material recycling. Yet, demolition is inevitable for a large part of the factory site. Primarily, the state of a large part of the buildings, together with their structural integrity, are not sufficient anymore to be easily repurposed or refurbished into new usable space. Therefore, a number of material flows will become available from the demolition of these structures, mainly comprising concrete and brick materials. Besides their raw reuse potential, the recovered materials can be used to illustrate the circular economy possibilities of construction waste, thereby serving as a local example which could be applied across the 40 other brownfield sites in Zagreb.

Other structures, such as the old management building, are suitable for repurposed use, after some minor renovations. Finally, both the old canning building and silos would be suitable for reuse, after being refurbished to fit for new uses, such as office spaces. Refurbishment therefore mainly entails restructuring of the building.

Figure 1. A small-scale MFA showing the material streams derived from the partial demolition of the Sljeme meat factory plant in Sesvete, Zagreb. Source: ERCO

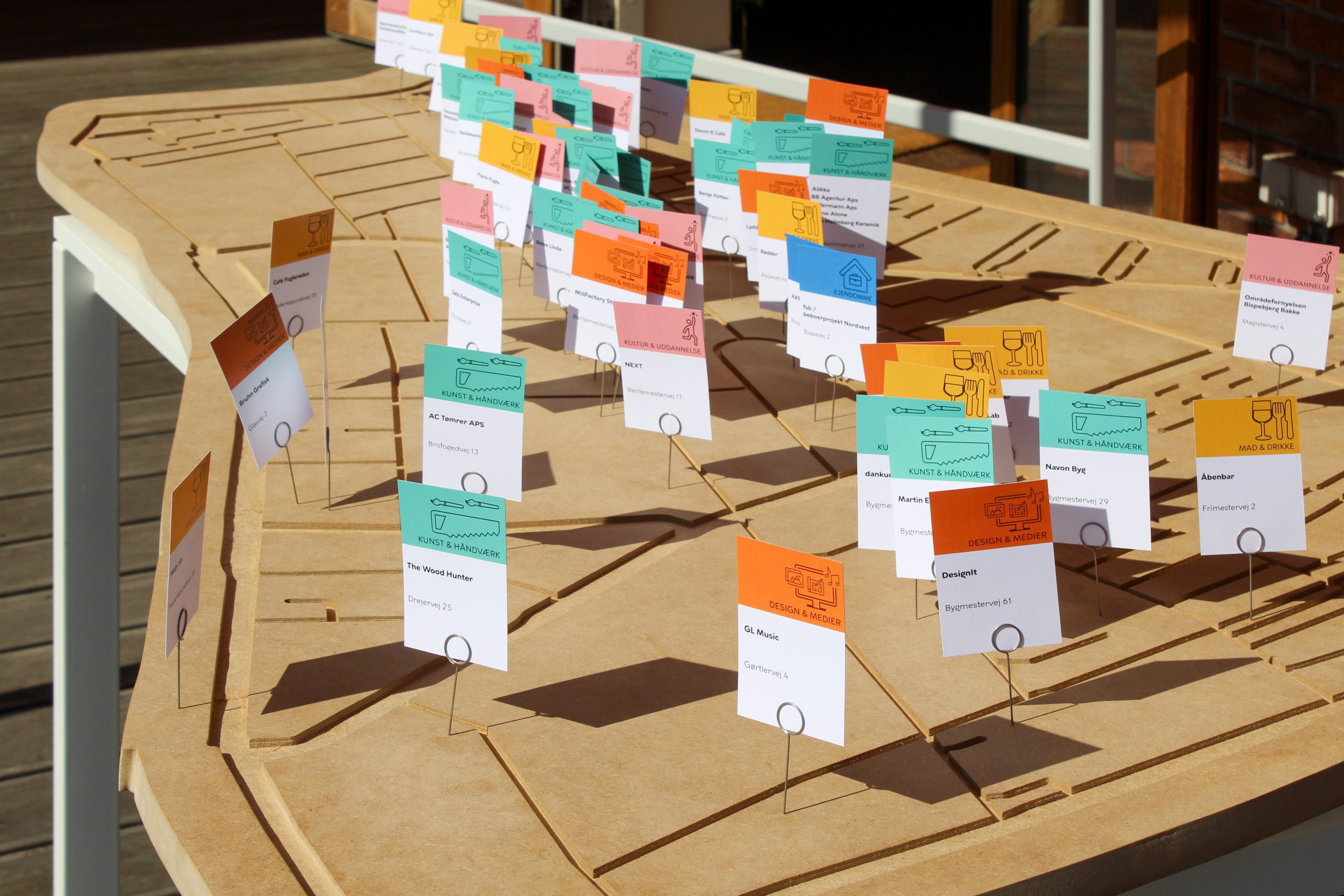

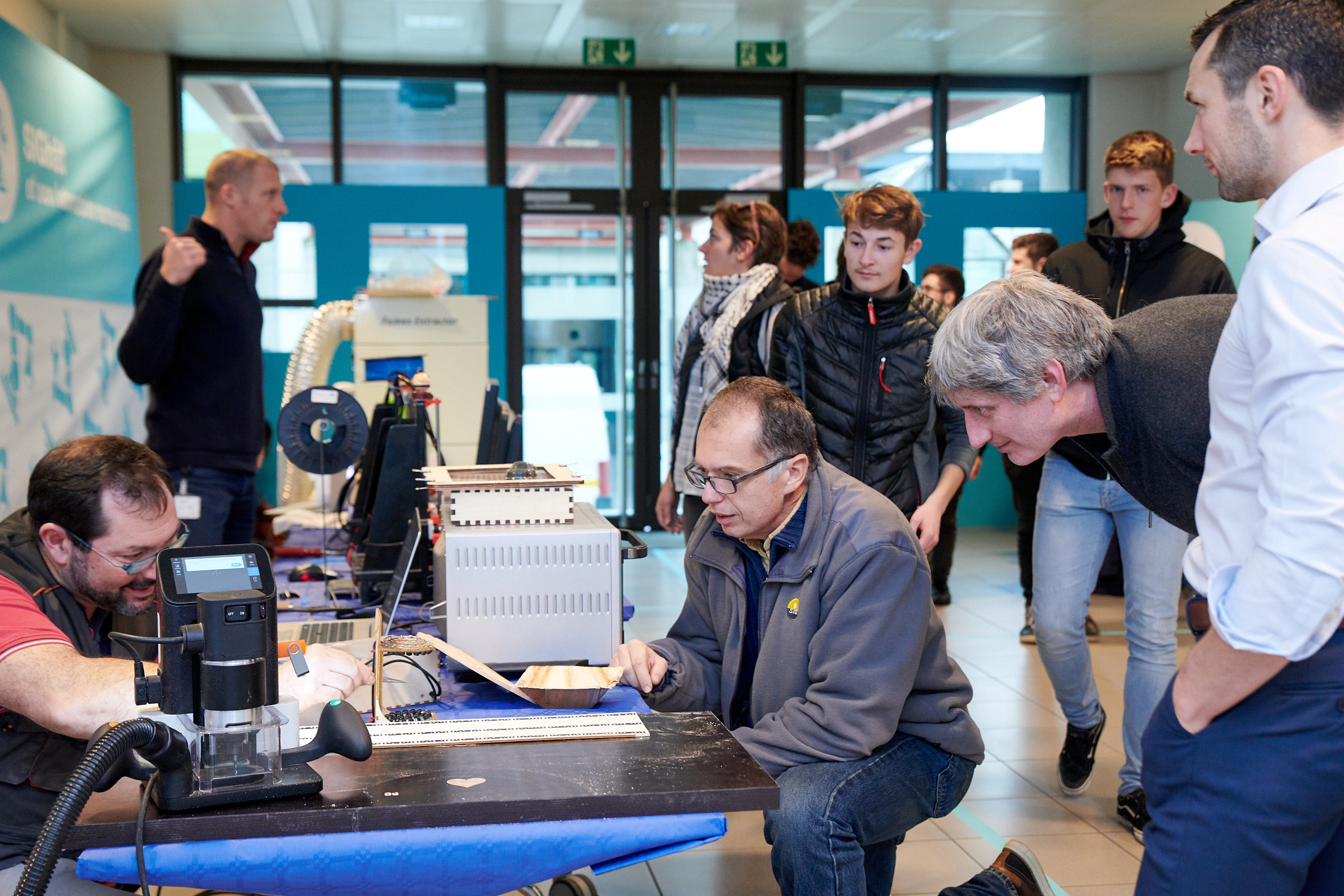

The destinations for these buildings and their materials was defined using an inclusive co-creation process with the local community. The co-creation efforts revealed the different community needs which should be integrated into the reuse of buildings: the fab city hub, a music school and a police station all became viable options. Another element in the co-creation process was based around the engagement of local youth in the circular process, which was done using a combination of design-thinking and practical skills engagement. Indeed, to engage the younger generation in the circular mindset, topics like product design including novel (bio)materials in construction waste reuse, or the digital fabrication and recycling of products, were discussed.

?

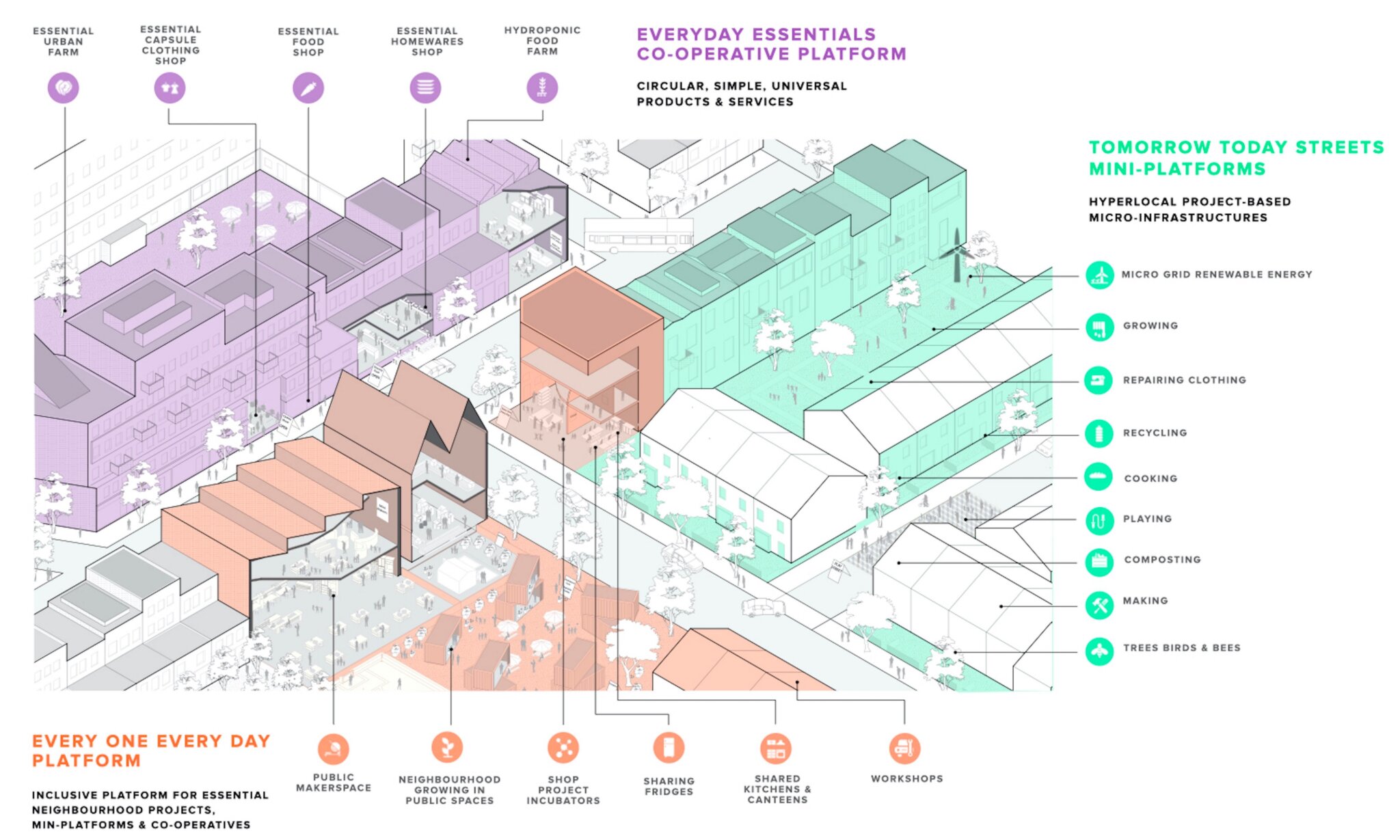

The HUB_S as a circular accelerator

The co-creation process and the involvement of local youth, are coordinated in the local innovation space HUB_S. Here, activities related to circularity and education are performed as part of an inclusive process with the local community, including different focus groups and users. As part of the schooling activities, our pilot is doing activities on skills development, including using different fabrication tools such as digital technology and analog production, thereby bringing together traditional crafts and heritage. Together, we are brainstorming how to reuse local resources from construction waste or other sources to develop new products. This is interesting not only because of the readily available construction waste resources on our pilot location, but also a living example for the urban mining potential across Sesvete and around the City of Zagreb.

Important in this process was the centrality of CENTRINNO principles for both the employees, business model, but also operational plans. The hub has been evolving as an innovation space already, where it once started as a multipurpose space under one roof, it is now evolving into the prototyping stages of a distributed hub where other parties could also be co-working. Indeed, the HUB_S maker space is seen as the less demanding and most open department, the fab lab as the prototyping department with more demanding needs, and finally the co-working space department which integrates facilities such as brainstorming rooms, conference spaces, services and facilities for SME’s. Now, the HUB_S is looking to expand by engaging with actors from primary and secondary schools, the Sesvete public university and finally some SME’s which could take their spot in the co-working space in the future. Currently these possible roles, synergies and hub-spots are still in the discussion phase, before the hub officially opens its doors.

Check out the article with interactive maps on CENTRINNO Cartography site!